ABS, with the full name Acrylonitrile Butadiene Styrene, is a ternary copolymer composed of acrylonitrile (A), butadiene (B), and styrene (S). It combines the properties of all three components: acrylonitrile contributes high hardness, strength, heat resistance, and chemical corrosion resistance; butadiene provides impact resistance and toughness; while styrene offers high surface gloss, ease of coloring, and good processability. This combination makes ABS plastic a versatile thermoplastic material known for being "robust, tough, and highly rigid."

Application Fields:

Automotive Industry: ABS plastic is widely used in the automotive industry for components such as dashboards, steering wheels, door liners, control knobs and switches, ventilation ducts, bumpers, radiator grilles, air conditioner housings, handles, interior trim panels, acoustic insulation panels, door locks, and more.

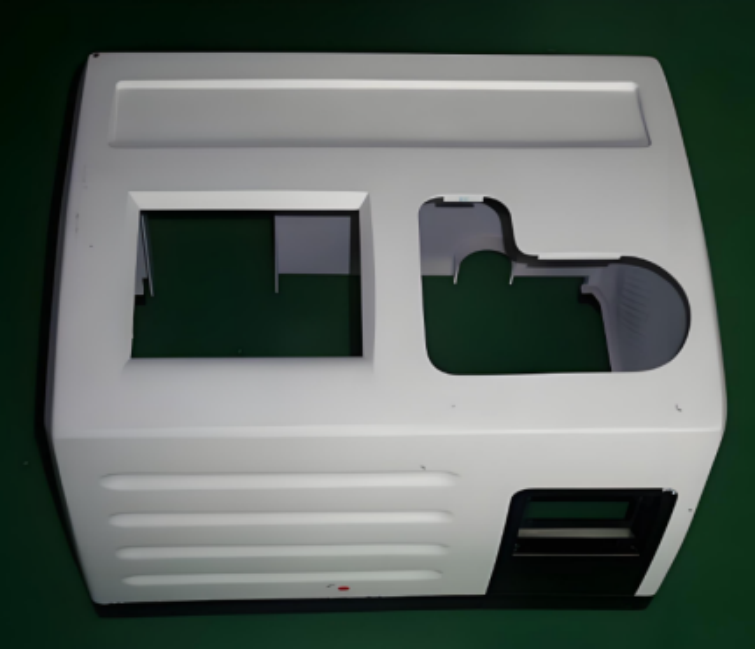

Electronics & Electrical Appliances: ABS plastic is utilized in the manufacturing of housings and internal structural parts for electronic products including televisions, refrigerators, washing machines, air conditioners, computers, mobile phones, digital cameras, and other devices.